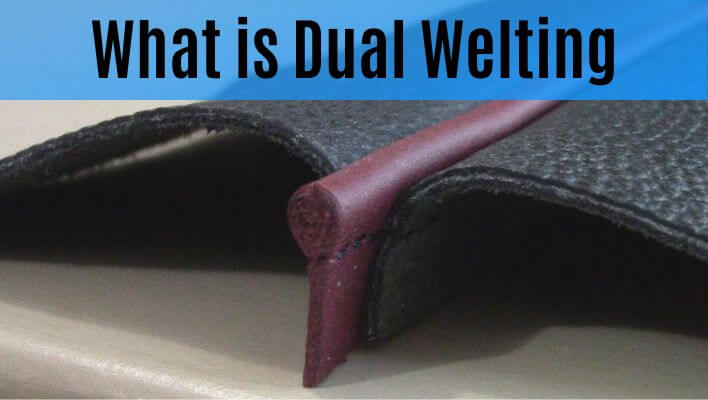

Dual welting, also known as double welting or double stitching, is a technique used in the construction of leather goods such as furniture, upholstery, belts, wallets, and footwear. It involves attaching two layers of leather together to create a stronger and more durable product.

This technique is often used in products that are frequently used and subjected to substantial wear and tear. The extended break-in period provided by dual welting also adds to the durability and longevity of the product.

Double welting is a common finishing element used in many leather goods. It is used to hide the raw edges, staples, pins, or nails for an elegant look. The technique of double welting is used to join two rows of piping.

This provides an aesthetic appeal and makes the product look polished and professional. The use of double welting is an indication of the high quality of the product, and it is considered a sign of craftsmanship and attention to detail. And now, many great baseball players prefer dual-welted gloves.

Benefits of Dual Welting

Content Summery

Dual welting is a technique used in the construction of leather goods such as furniture, upholstery, belts, wallets, and footwear. It offers several benefits that can make the product more durable, long-lasting, and visually appealing.

Firstly, the two welts provide additional support and stability, which helps to prevent the product from separating or wearing out quickly, making the product more durable.

Secondly, the welts help to conceal the edge of the product, which can make it look more polished and professional, providing an aesthetic appeal to the product.

Moreover, it allows for more flexibility in product design, as it allows for the use of different colors or types of leather for the welts. The use of different materials can give the product a unique and personalized look.

It also increases the overall strength of the product, making it more resistant to wear and tear. It is considered a higher-quality method of construction, and the products that have been constructed using this technique are often considered to be of a higher quality. Dual welting is also used in products that are frequently used and subjected to substantial wear and tear, which increases the product’s lifespan and makes it more durable.

What is dual welting on a baseball glove?

Dual welting on a baseball glove refers to the process of attaching two strips of leather, known as welts, along the edge of the pocket of the glove. This technique is used to create a stronger and more durable pocket, which helps to improve the overall performance of the glove.

The welts are typically made from the same leather as the glove and are attached using a special stitching method. This creates a strong and durable bond between the welts and the rest of the glove, which helps to prevent the pocket from breaking down or becoming too worn over time.

Dual welting on a baseball glove is considered a higher-quality method of construction, as it provides better durability and performance compared to other methods.

What is the best webbing for a welted baseball glove?

When it comes to welted baseball gloves, the webbing is an essential component that determines the durability, performance, and overall quality of the glove. The webbing is the material that makes up the pocket, which is the area of the glove where the ball is caught.

There are several types of webbing that can be used for welted baseball gloves, each with its own advantages and disadvantages. Here we will discuss the three most popular options: leather, synthetic and hybrid webbing.

Leather Webbing

Leather is a traditional and durable material that is often used for welted baseball gloves. It is strong, flexible, and can be shaped to fit the contours of the glove.

The natural grain of the leather gives the glove a classic and stylish look. Leather webbing also tends to be more comfortable as it molds to the shape of your hand over time. However, leather webbing is also heavier than synthetic materials and may not be as breathable, which could cause your hand to sweat.

Synthetic Webbing

Synthetic materials such as nylon or mesh can also be used for welted baseball gloves. They are lightweight, which can make the glove easier to maneuver. Synthetic webbing is also generally less expensive than leather webbing.

Additionally, synthetic webbing is often more breathable, which can help to keep your hand cool and dry. However, synthetic webbing is not as durable as leather and may not last as long.

Hybrid Webbing

Some manufacturers use a combination of leather and synthetic materials for their welted baseball gloves, which is known as hybrid webbing.

This provides the best of both worlds, with the durability of leather and the flexibility of synthetic materials. Hybrid webbing is often more expensive than using just one material, but it offers the best balance of durability and flexibility.

Advantages of Welted Gloves

Welted gloves, also known as welted work gloves, are gloves that have a strip of leather, known as a welt, running along the edge of the glove’s finger openings. These gloves have several advantages:

- Durability: These gloves are more durable than non-welted gloves because the welt helps to reinforce the edge of the glove, making it more resistant to wear and tear.

- Comfort: It is often more comfortable than non-welted gloves because the welt helps to keep the glove snug against the hand, reducing the likelihood of slippage.

- Protection: It offers added protection to the fingers and hand, as the welt helps to keep the gloves securely in place and helps to protect the fingers from scrapes and cuts.

- Aesthetics: Furthermore, it often has a polished, professional look due to the welt, which gives an aesthetic appeal.

- Variety: The gloves come in a variety of materials and styles, so they can be used in a variety of different applications, such as work, outdoor activities, and even fashion.

- Customizable: It can be customized by using different types of leather or synthetic materials for the welt, which allows for a greater degree of personalization and style.

- Resistant to wear and tear: These gloves are often used for work or outdoor activities and are subjected to substantial wear and tear; these gloves are designed to withstand heavy use and last for a longer period of time.

Conclusion:

In summary, dual welting on a baseball glove is a technique that is used to make the pocket of the glove stronger and more durable. By attaching two strips of leather, known as welts, along the edge of the pocket, a strong bond is created between the welts and the rest of the glove, which helps to prevent the pocket from breaking down or becoming too worn over time.

This improves the overall performance of the glove, making it more durable and resistant to wear and tear. Dual welting is considered to be a higher-quality method of construction compared to other techniques, which is why it is a preferred choice for baseball players who want a high-quality and durable glove that will withstand heavy use and last longer.

FAQs

Q. What is the purpose of welting?

The purpose of welting is to provide additional support and stability to the edge of a product, such as a leather good, by attaching a strip of leather, known as a welt, along the edge. This helps to prevent the product from separating or wearing out quickly and also provides a cleaner and more finished look.

Q. What does dual welting do?

Dual welting is the process of attaching two strips of leather, known as welts, along the edge of a product. This technique increases the overall strength and durability of the product, making it more resistant to wear and tear and providing a cleaner, more finished look.

Q. Is Dual Welting better?

Dual welting is considered a higher-quality method of construction because it increases the overall strength and durability of the product, making it more resistant to wear and tear. It also provides a cleaner, more finished look and allows for more flexibility in product design.